Experience what you can't google

Explore the unique features that set Advanced Engineering apart — from hands-on tech zones to focused networking areas designed to connect you with the right solutions

What's new?

NIO EP9 by RML Group

NIO EP9 topped 310km/h (193mph), hit 0-100km/h in 2.7 seconds, had enough downforce to generate 3G in 100mph corners and three tonnes of downforce at 300km/h (186mph) – which is more than an F1 car.

FB3 Cargo Drone (multicopter) by Flying Basket

With a payload capability of up to 100kg the FB3 is the first in its class.

Solar powered wing for High Altitude Platform Satellite

HAPS wing (1.6m) that integrate 10 high performance Maxoen solar cells Gen8 in series.

Show floor features

Experience groundbreaking innovations in person. See the technology up close, hear the details from experts, and understand how they’re shaping the future of sustainable engineering.

Sneak Peek

- Waste2Race hydrogen-powered car fueled by sewage, aiming to break a land speed record

- Jota Hypercar with advanced Maxon photovoltaic cells

- Wing of Tomorrow: solar-powered high-altitude UAV with composite electric propulsion wing

- Full-scale composite vertical stabiliser from Munro Technology highlighting aerospace innovation

Register to be the first to hear what else is building behind doors.

Discover the power of pavilions

Dedicated pavilions bring together forward-thinking companies, cutting-edge technologies, and practical solutions in one focused environment. Whether sourcing new suppliers, exploring innovation, or solving complex engineering challenges, pavilions offer unparalleled access to what’s next.

This year’s new pavilions:

You will find new dedicated spaces designed to meet evolving industry needs:

✈️ ADS Pavilion: Innovation focused on aerospace, defence, and security.

🚀 SME Pavilion: A spotlight on high-growth small businesses and emerging technologies.

🧪 Composites Village: A hub for advanced materials and lightweight solutions.

Each pavilion delivers targeted insights, efficient networking, and exclusive opportunities to discover breakthrough engineering solutions.

NIO EP9 by RML Group

We designed and engineered the world’s fastest electric vehicle. In just 14 months we delivered the NIO EP9 that topped 310km/h (193mph), hit 0-100km/h in 2.7 seconds had enough downforce to generate 3G in 100mph corners and three tonnes of downforce at 300km/h (186mph) – which is more than an F1 car. The performance demanded an unprecedented braking system and passive cooling system to maintain optimum temperatures. The design also included an interchangeable battery system that permits quick battery changes in line with the design ethos created by NIO.

A total of 16 cars were built for the OEM and we achieved an outright EV lap record at the Nürburgring, Nordschleife in 2017 at 6:45.9, along with the autonomous lap record at COTA at 2:40.330.

VX4 by THE ROCKWOOD GROUP

Rockwood Aerospace has developed a novel manufacturing process for propeller blades tailored to electric vertical take-off and landing (eVTOL) aircraft. For Vertical Aerospace’s VX4 Prototype Aircraft it developed a proprietary single-shot compression moulding technique that integrates carbon fibre pre-preg, foam cores, and metallic hardware in one cure cycle. This eliminates secondary bonding, yielding blades that are lighter, stronger, and more fatigue-resistant than those from resin infusion or bonded skin-and-spar methods.

The process is supported by Rockwood’s custom tooling and hot platen presses, enabling complex geometries and precise fibre placement. Few UK firms combine this expertise with scalability, giving Rockwood a clear advantage in the fast-growing eVTOL sector.

For operators, the benefits are direct: reduced aircraft weight, meaning longer battery endurance, and enhanced safety. With global eVTOL markets projected to increase ~20-fold within a decade, Rockwood’s technology positions it for contracts with leading OEMs while also supporting their current aerospace and defence markets.

Jota Hypercar

The Hypercar class is the top-tier category in the FIA World Endurance Championship which features two types of car:

- LMH (Le Mans Hypercar)

- LMDh (Le Mans Daytona h)

These two types of car will compete against eash other in the FIA WEC LMDh is also eligible to compete in the IMSA WeatherTech SportsCar Championship and, therefore, to race in both the 24 Hours of Le Mans and the Rolex 24 at Daytona.

Press Molded MV Agusta F3 RR Single Piece Body Part

Unique feature is the fact this part had been press-molded in a single stage, featuring integrated fixture built using re-cycled carbon fiber. The KSP stands in the high capacity stated in 40 units / day / mold.

Toyota Hilux prototype hydrogen fuel cell pick up vehilce and rolling chassis

Toyota is committed to achieving carbon neutrality by implementing a diverse range of powertrain technologies, including hybrid, plug-in hybrid, battery electric, e-fuels, hydrogen fuel cell electric and hydrogen combustion. This multi-path strategy enables customers to adopt sustainable vehicles tailored to their requirements, from everyday driving to motorsport, without compromise. Recognising hydrogen’s vital role in future clean energy systems, Toyota is at the forefront of developing both fuel cell and combustion hydrogen solutions. The innovative Toyota Hilux hydrogen fuel cell prototype, built at Toyota Motor Manufacturing UK, exemplifies the adaptability and potential of hydrogen technology for practical applications.

Ultra-high-speed Industrial 3D Printer

On 29th October, UK based CONSTRUCT3D will reveal its next-generation industrial 3D printer: Construct 2.

Building on a legacy of extreme performance systems, the Construct 2 is engineered for uncompromising speed, precision, and durability. Purpose-built for continuous 24/7 operation, it is a true production workhorse capable of handling even the most demanding engineering polymers.

Where previous industry standards delivered 1-2 kg throughput per day, Construct 2 surges ahead with up to 8 kg daily – maintaining consistent material integrity and dimensional accuracy. Intelligent monitoring and process control ensure reliability and repeatability, driving significant gains in efficiency and production uptime.

Please come to the AM FUTURES stand N134 – Launch 10:00am 29th of October.

FB3 Cargo Drone (multicopter) by Flying Basket

The FB3 drone is designed to revolutionise logistics both onshore and offshore. With a payload capacity of up to 100 kg, it enables fast, safe, and emission-free transportation where traditional methods like helicopters or cranes are costly, slow, or impractical. Whether delivering equipment to offshore wind turbines, transporting goods in remote mountain areas, or supporting industrial operations in challenging environments, the FB3 makes aerial lifting accessible and efficient. We make aerial lifting and transportation available to all industries.

Munro Stabaliser by iSurface

Composites are indispensable for lightweighting, yet their complex failure modes — such as barely visible impact damage (BVID) — limit confidence and drive costly overdesign.

In use cases such as aircraft tail sections and wing leading edges, Foreign Object Debris (FOD) remain one of the most insidious and costly risks in aerospace maintenance and safety. Even small, seemingly insignificant debris—gravel, dropped tools, or inadvertent footfall—can cause BVID that evades traditional inspection methods but may initiate catastrophic failure over time.

iSurface directly addresses this challenge by embedding conductive fibre innovations into composite architectures, enabling the capture of structural data at the material level.

This data is processed through an AI-powered acquisition and predictive analytics platform, delivering continuous health monitoring, early fault detection, and robust decision support.

iSurface is a collaborative project by Munro Technology, Z Prime and Axalp Technologies AG, redefining how composite materials are monitored, maintained and trusted in aerospace.

Aircraft Wing

Aircraft Wing prototype from Swift Technology Group Ltd.

RML P39 by STC

RML vision for the P39 was clear: to create a definitive interpretation of a Le Mans Hypercar-inspired GT—delivering an uncompromising fusion of all-round performance, refinement, and usability.

With over 40 years in motorsport and engineering expertise, the P39 is engineered to thrill without compromise. Every journey, whether across continents or around a racetrack, is an experience defined by power, precision, and poise.

With its lightweight carbon body, race-bred dynamics, and refined comfort, the P39 stands alone, delivering a driving experience that few others can match, and none can surpass.

Many cars aspire to be the ultimate GT, only the RML P39 lives up to that promise.

Solar powered wing for High Altitude Platform Satellite.

HAPS wing (1.6m) that integrate 10 high performance Maxoen solar cells Gen8 in series. The skin is made from novel fibres (TENRON) and coated with special epoxy compatible with composite structure, it has superior durability for weather and high impact toughness.

Supreme Coatings automated Cerakote robotic spraying machine. *First in the UK* by AM Futures

Supreme Coatings introduce for the first time in the UK the future of coating technology with our advanced Cerakote robotics program. The demonstration system showcases how state-of-the-art robotics ensure precise, consistent, and high-quality Cerakote application every time. Discover the key benefits of robotic application, including improved durability, efficiency, and performance across various industries.

Composites’ closed moulding technique

A chance to get up close to the new composites’ closed moulding technique, which is taking the industry by storm. At this year’s Advanced Engineering show, Alan Harper Composites will feature a demo area demonstrating the ease with which reusable vacuum membranes are safely manufactured. The live event will dispel some of the myths surrounding this innovative economic method, also allowing visitors to engage in learning more about it. The technology has now made significant inroads into all sectors of composite manufacturing, ranging from the modest open-mould hand-lay parts to advanced composite aerospace applications. Complementing this success with reusable membranes, large-scale printed moulds will also be exhibited. Alan Harper Composites will demonstrate how easily the silicone reusable membrane can be installed and instantly vacuum-sealed, ready for infusion or Autoclave moulding.

3D printed composite mould tool and corresponding part by LATI

Fuselage by BRETON

Autoclave-ready composite layup tool

Key features:

- Size: 2.900 x 1.700 x 760 mm

- 3D printed & machined on Breton Genesi E4

- Material: THERMOCOMP EC004EXAR1

- Average printing flowrate: 51 Kg/h

- Layer orientation: 45° for optimized thermal expansion and warping control Printing Time: 11 hours

- Machining Time: 21 hours

ARC C600 by ARC Aero Systems

The ARC C600 is an advanced fixed-wing electric Vertical Take Off and Landing e-VTOL Unmanned Aerial System (UAS) designed for efficient, heavy-lift air cargo operations. Combining the vertical take-off flexibility of multirotor systems with the speed and range of fixed-wing aircraft, it eliminates the need for runways or launch equipment. With a 100 kg payload capacity and Beyond Visual Line of Sight (BVLOS) capability, the C600 can cover distances of up to 400 km, offering a rapid and reliable logistics solution for manufacturing, energy, and remote-site operations. Its hybrid design enables stable flight in diverse weather conditions, reducing downtime and improving delivery efficiency. The C600’s electric VTOL technology represents a new era of sustainable aerial logistics, significantly cutting operational time and infrastructure costs. As a versatile platform capable of autonomous missions, it bridges the gap between short-range drones and manned cargo aircraft, redefining the possibilities of modern air transport.

Lotus Evija and Lotus Emira by Lotus Engineering

First revealed in 2019, the Lotus Evija is designed, engineered and hand-built by Lotus in Hethel, UK, in a dedicated facility historically used for Lotus Engineering projects including the Lotus Carlton and Tesla Roadster. Four electric motors combine to deliver 2,039 PS. With no mechanical connections, the system is entirely governed by Lotus’ software, developed to deliver Lotus character in an EV hypercar. Evija is the world’s lightest production EV hypercar; its carbon-fibre monocoque weighs just 120 kg. The mid-mounted battery pack centralises mass for a mid-engined feel, while double wishbone suspension and inboard damping optimise dynamics. Range is up to 314 km (WLTP Overall) from the 91-kWh battery, with 800V 350 kW DC and 400V 22 kW 3-phase AC charging capability.

The Emira represents the latest development of Lotus’ bonded, extruded aluminium chassis architecture, pioneered on the Elise and since proven across multiple OEM programmes. Emira’s chassis, subframes, fuel tank and other key components are manufactured at Lotus Advanced Structures in Norwich, where we also offer contract manufacturing expertise for precision machined, laser cut and fabricated components. Emira’s construction allows efficient adaptation, such as wheelbase changes, with only modest re-tooling for cost-effective flexibility. Assembly takes place at the Chapman Production Centre in Hethel, UK, using a combination of advanced automation and skilled handcraft. The state-of-the-art facility was designed to accommodate variation in model type and production requirements. Emira is the fastest-selling Lotus ever; the 10,000th car left Hethel in December 2024. With in-house expertise in chassis systems, advanced controls, and production engineering, Lotus offers proven capability for low-volume, high-performance contract manufacture.

Dynium Fruit Transport by Dynium

WRe4 Racing Car by Warwick Racing

Warwick Racing is the University of Warwick’s Formula Student team. Each year, students from a range of disciplines work together to design, build, and race a single-seater car. The team operates like a motorsport organisation, giving members practical experience in engineering, business and project management. Competing in the Formula Student UK competition, Warwick Racing focuses on creating an efficient and reliable electric race car. Over the course of the year, the team works on the design, manufacturing, and testing of the car to ensure strong performance at competition. Warwick Racing has produced seven generations of combustion vehicles and four generations of electric vehicles. Now, after a successful competition last July with WRe4, our focus has shifted to designing and producing our fifth-generation EV, WRe5. More than ever, we are determined to make this season our most successful yet!

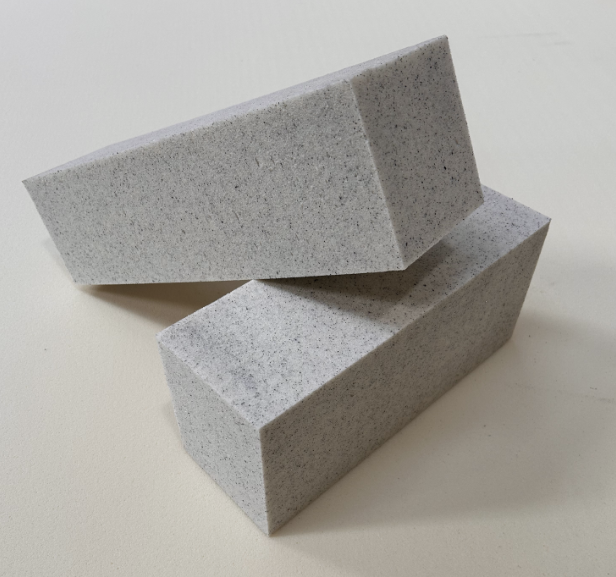

Tripor 227 FR by Trident Foams

Tripor 227 FR is a new-to-market, lightweight, flame-resistant, two-part 48kg polyurethane foam system. Offering strength, excellent adhesion, and efficient insulation, it meets EASA CS25 / FAR 25.853 standards. Ideal for infill, mouldings, and insulation, Tripor 227 FR delivers safe, strong, and sustainable performance with an exceptionally low environmental impact.

The TWR Supercat

A mix of traditional and modern, TWR is the perfect companion or road and track. Penned by a digital forward designer with input from rock and roll traditionalism, developed using tried and tested technology bolstered with modern techniques.

Composites UK Pavilion Returns Bigger than Ever

The Composites UK Pavilion Stand (W170) is returning to Advanced Engineering bigger and better than ever, providing an unrivalled platform for the UK composites sector. This year, the pavilion will host more companies than before, showcasing the latest innovations, products, and expertise driving growth in advanced materials. By expanding its footprint, Composites UK is strengthening opportunities for networking, collaboration, and knowledge exchange across the supply chain. The stand offers member companies enhanced visibility at the industry’s leading exhibition, underlining the association’s commitment to supporting business development and promoting the UK as a global leader in composites.

🌟NEW🌟: ASCEND’s Impact with GKN Aerospace

For the first time at Advanced Engineering, GKN Aerospace will present on the show floor, showcasing the ASCEND programme’s significant advancements. Attendees will have the opportunity to examine key components and structures developed as a direct outcome of this landmark initiative.

The ASCEND programme has successfully met its technological objectives while establishing a new paradigm for cross-sector collaboration. It has created a resilient supply chain and a highly skilled workforce, underpinning future innovations in composite manufacturing.

Visit GKN Aerospace at Advanced Engineering to engage with the programme’s innovations firsthand and connect with the technical experts advancing the future of composite manufacturing.

Composites Networking Lounge

As the ONLY UK meeting place for the composites industry, the Composites Networking Lounge will be recharged and better than ever in 2025. It is powered by PRF Composites Materials.

- NEW: PRF’s REEPREEG live demo, a revolutionary process completing fibre-reinforced polymer curing in just 5 minutes at 160°c. – ONLY at Advanced Engineering 2025

- NEW: Dedicated industry networking sessions for Aerospace, Motorsports, Automotive, Medical, Marine & Maritime, Defence, Sports & Leisure, and Renewables.

- Composites components display and much more.

Auto & Aero Networking Lounge

Powered by Atlas Copco & ISRA VISION, along with its top-tier partners, visitors to the lounge will gain insights into state-of-the-art tooling and smart manufacturing solutions.

Expect to get up close with F1 car showcases and advanced assembly technologies, from smart tooling and software to Machine Vision Solutions that are setting new standards in optimising production, improving efficiency, and enhancing quality across the manufacturing industries.

The Innovation & Sustainability Trails

The innovation and sustainability trails allows you to follow on one of our guided tours or at your own leisure!

You will discover the latest, greenest developments from our exhibitors at the show, conveniently marked on the pocket guide, map and show app.

The Conference Programme

Choose from 5 forums to further develop your career and find inspiration for your future projects.

Each stage covers Innovation, Sustainability, Digitalisation, Government and Policy, and Levelling-Up and Skills.

Hear from peers who have been through your challenges, and come out the other side stronger.

Networking opportunities

The Composites and the Auto & Aero Networking lounges offer the perfect relaxing space to catch up with industry peers and meet new likeminded engineering professionals.

Features on the show floor

You’ll find prototype models of electric aircraft, an advanced marine engine, an interactive BEDEO Van, and the incredible Crusher Robot, among many other exciting exhibits.

Register today to start planning your visit and make sure you don’t miss a thing! See some of the confirmed features below…

What does Advanced Engineering mean for the industry?

We asked visitors and this is what they told us

Miss out on last year? Catch up here!

Best Sustainable Stand competition

At Advanced Engineering 2024, innovation meets sustainability in an exciting showdown! Witness the ‘Best Sustainable Stand Competition,’ where cutting-edge engineering and eco-conscious design collide.

Exhibitors will showcase their ingenuity by creating stands that captivate the audience and highlight their commitment to a greener future.